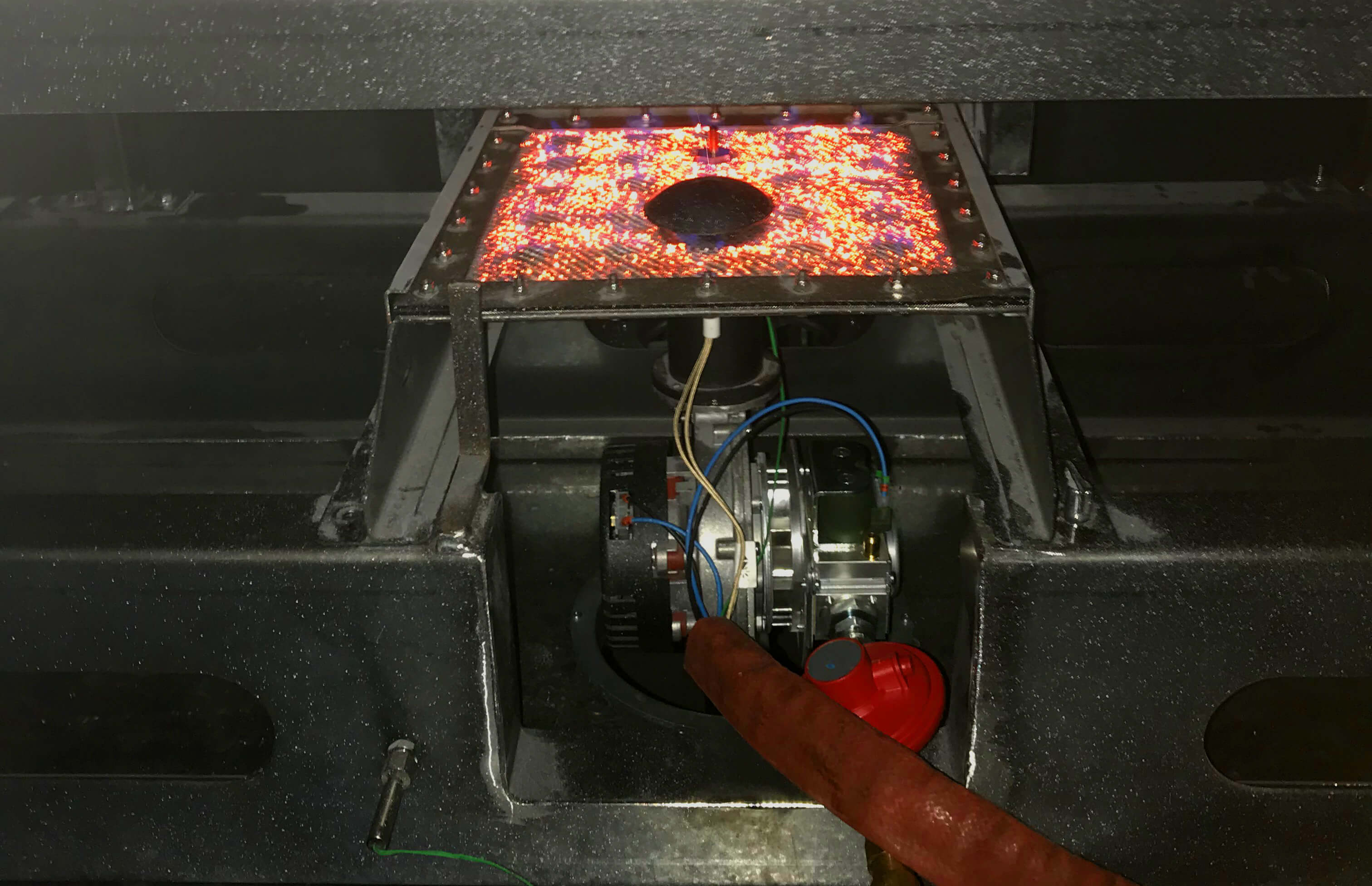

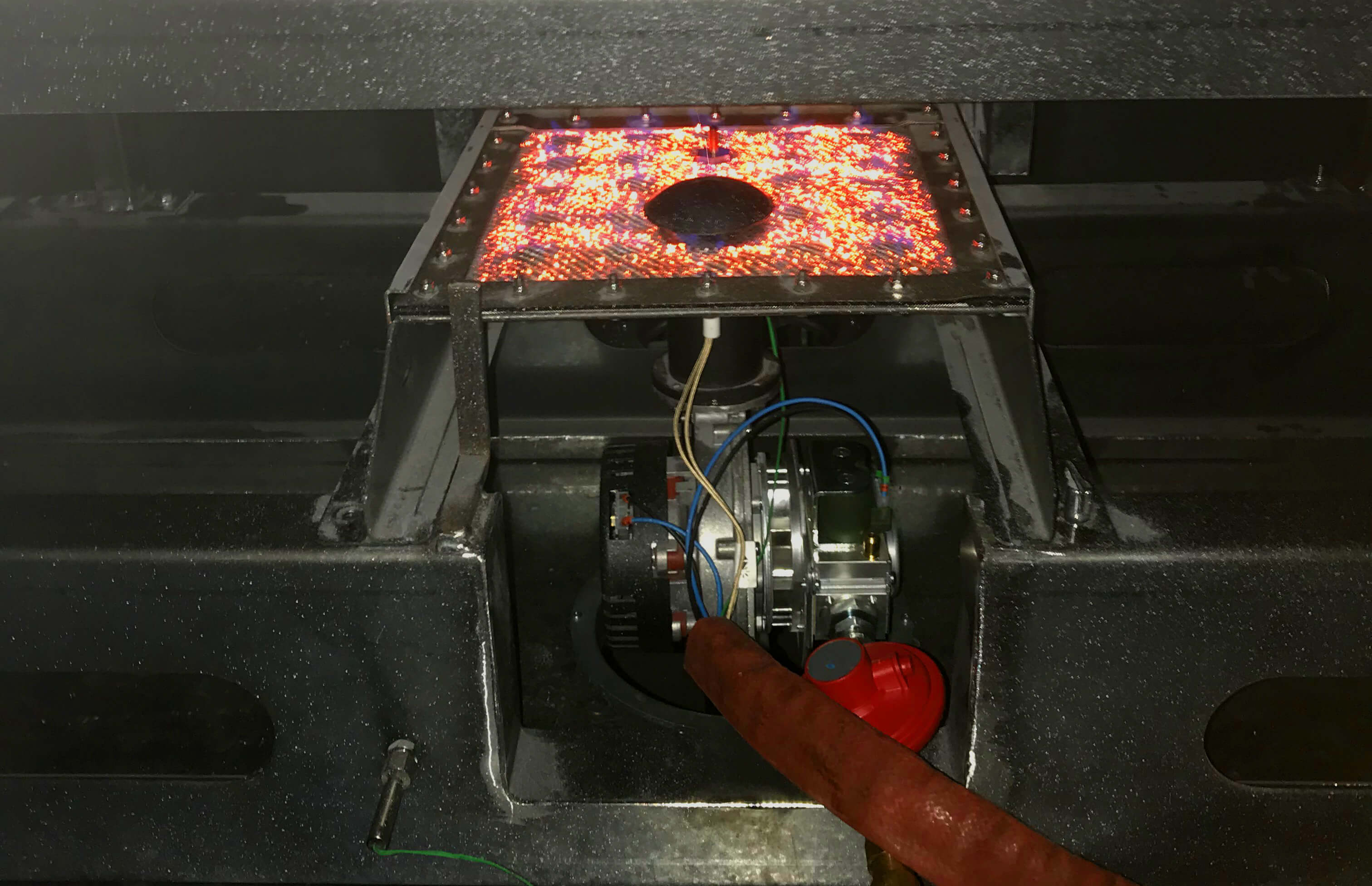

Pre – Mix Gas Burners

About Gas Burners

Smaller premix nozzles are used in many cases as gas pilots, designed to offer a reliable and efficient means of igniting a wide range of industrial gas, oil or dual fuel burners.

Uses of these burners are found across a wide span of industries with a variety of uses including;

– Asphalt heating equipment

– Kitchen equipment

– Large space heating

– Drying equipment

– Printing equipment

– Food/Pharmaceutical machinery

Combustion Characteristics

– Use of high temperature: 1100 ℃ (upper limit temperature 1250 ℃)

– Load adjustment range: Infrared burner mode: 100-800kw / m2 Blue flame combustion mode: 1000-10,000kw / m2

– Small resistance:

Infrared burner mode: less than 50pa Blue flame

Combustion mode: less than 200pa

– Long life: 20,000h

– High radiation efficiency:> 50%

– Even burning

– Thermal inertia: Fast heating and cooling

– Thermal shock: Dramatic changes in the thermal load will not cause damage to the material

– Resistance to mechanical shock: Some mechanical impact, no effect on the material

– Can be made into complex burner shapes

Related Projects

Finishing & Detail

– Painting

– Pre-Treatment

– Powder Coating

& more

Laser Cutting

Alpha Systems: Construction

– Tear-downs & Haul-offs

– Site Management

– General Building & Construction