Alpha Systems Fabrication proud supplier to Thermal Road Repairs

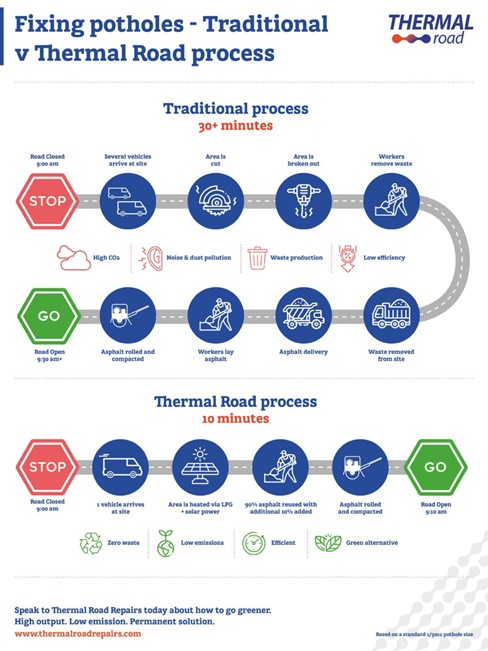

We are proud to supply Thermal Road Repairs with equipment that is powered by sustainable energy sources, and in turn creating a more efficient process for fixing potholes. Here is a graphical explanation of why Thermal Road Repairs pothole repair system is faster and greener than traditional road repair processes.

What are the Challenges with traditional pothole repairs?

High CO2 emissions

Noise & Dust Pollution

Waste Production

Low efficiency

Road Closures for long durations

The Solution – Thermal Road Repairs Process:

Jointless Repair (Elimination of any formed edge, negating future maintenance issues)

Sustainable Method (Utilise 80-90% Recycled Materials)

Cost Effective (Improved value for money against other existing systems)

Thermal infrared heaters, which use LPG and power gained from its in-built solar panels, to heat up failed and failing material in potholes and surrounding asphalt. The existing asphalt is then mixed with a small quantity of new asphalt to create a homogeneous material that is then compacted with a Roller.

Due to the asphalt around the edges also being heated there is no joint; the material all bonds together preventing the pothole from reforming.

Thus, the repair process is much faster then traditional techniques, there is no need to break out the defect, by cutting or jack hammering which reduces noise and dust pollution. The products & equipment required are contained within one repair unit.

Results:

The London Borough of Richmond reported a saving of between 20-30% whilst using the Thermal Road Repairs staff to operate their machinery. They believe that their next step is to train their workers to this standard.

The Borough were impressed with Thermal Road Repairs’ credentials and their process, which is 80% more environmentally friendly than traditional methods. Their method produces on average 0.4 tonnes of CO2 per 8-hour shift, compared to 2.4 tonnes for traditional techniques.

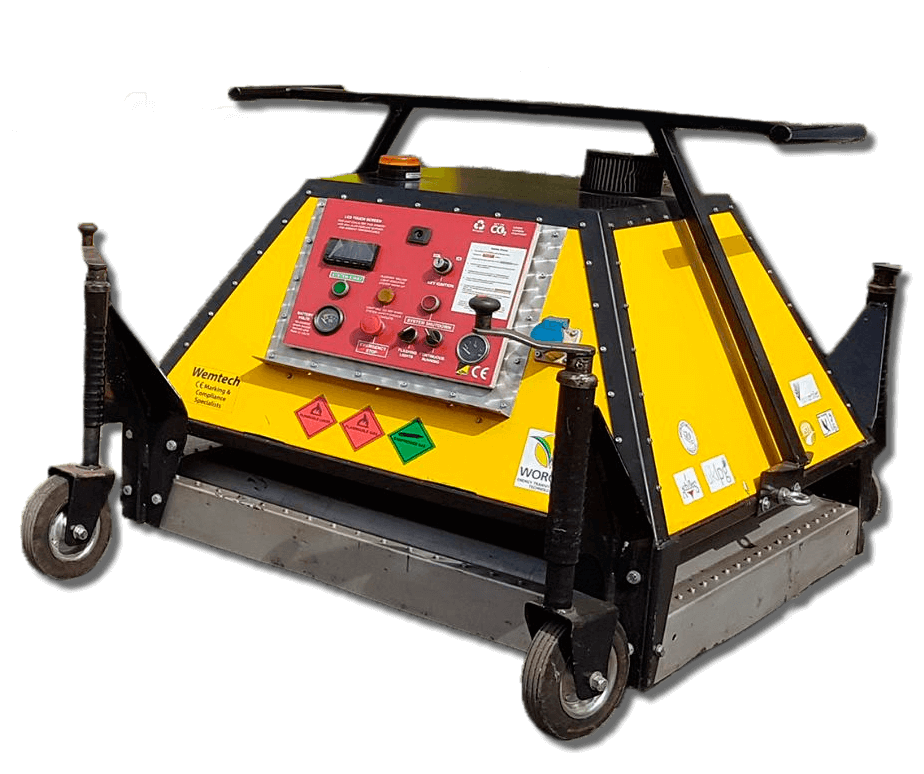

The Equipment (This is where we come in!):

We designed and manufactured the back of the Utility Patch Repair vehicle for Thermal Road Repairs, the newest piece of equipment within their portfolio. It presents a complete self-contained solution enabling best practice in all areas of their industry. The vehicle helps Thermal Road Repairs to deliver a cost effective, efficient, sustainable and approved method that is helping local authorities use their budgets to a maximum by investing in a ‘right first time’ solution for asphalt repairs.

We also designed, fabricated & assembled in house the paver mounted repair heater. It is attached to the side arm and side plate of any asphalt paver, enabling heating of the cold longitudinal joint to simulate echelon paving.

The thermal repair heaters (designed, fabricated & assembled by Alpha) offers a quick, easy way to permanently repair surface defects such as potholes, joint failures and reinstatements around manhole covers.

Equipment Sustainability

This equipment where able is powered by solar panels, meaning it is more environmentally friendly as well as creating a more sufficient process.

Here at Alpha Systems Fabrication, we can tailor our products to meet your specifications and requirements.

#potholes #potholerepairs #thermalroadrepairs #greentechnology #lowcarbonemissions #zerowaste #lownoisepollution #costefficient #greenalternative #highoutput

Sources:

https://www.thermalroadrepairs.com/london-borough-of-richmond-making-funds-go-further/

0 Comments